domingo, 30 de julho de 2017

Magnetic and Electric Characterization of Materials for Electrical Machines by M.S.Muhit -Royal Institute of Technology School of Electrical Engineering Electrical Machines and Power Electronics

Magnetic and Electric Characterization of Materials for Electrical Machines

by M.S.Muhit

Master Thesis

Royal Institute of Technology School of Electrical Engineering Electrical Machines and Power Electronics Stockholm, August 2011

Abstract

This thesis aims to characterize materials for electrical machines. Electromagnetic properties (b-h curves) and electrical resistivity were the main properties investigated in the project work. Two types of samples are considered: stator lamination sheet and rings made of steel used for structural pieces in large AC machines. To facilitate magnetic characterization experiments, an existing test setup was upgraded. Sensors and amplifiers have been developed. The control system has been upgraded and developed SIMULINK modules have been adapted to dSPACE GUI. The retrieved ‘B’ and ‘H’ signals are processed offline to obtain the results. The lamination sheet has been tested for frequencies in the range [0.1-150 Hz] and flux density levels up to 1.5 T. The obtained results depict characteristics hysteresis curves and measured loss figures. The ring samples (structural steel) are characterized to explore the B-H curves at frequencies in the range [0.1-250 Hz] and field intensity up to 900 A/m. For resistivity measurements of the lamination sheets and ring samples, standard resistivity measurement techniques have been implemented. Keywords Magnetic properties, Epstein frame, hysteresisgraph, four point probe, resistivity measurement, soft magnetic material, electrical steel.

VIEW FULL TEXT

http://www.diva-portal.org/smash/get/diva2:470656/fulltext01

Measurement research on magnetic properties of electrical sheet steel under different temperature, harmonic and dc bias Dezhi Chen - Li wei Fang - Byung-il Kwon School of Electrical Engineering, Shenyang University of Technology

Measurement research on magnetic properties of electrical

sheet steel under different temperature, harmonic

and dc bias

Dezhi Chen - Li wei Fang - Byung-il Kwon

School of Electrical Engineering, Shenyang University of Technology,

Shenyang, China

I. INTRODUCTION

The phenomena such as the DC power grid, geomagnetic storms change, DC voltage of converter transformer may result in DC bias. Then the DC bias leads to the magnetic leakage flux increase in cores, metal structure losses, temperature rise, local overheating, dielectric breakdown, noise vibration, even the permanent damage to transformer.1 Meanwhile, the rise of temperature and harmonic will also affect the magnetic properties of electrical sheet steel. Manufacturers of electrical sheet steel can provide magnetic parameters, such as loss of iron core, that usually are measured at room environment temperature. The measured electromagnetic performance of transformer has a certain error compared with the actual operation temperature.2 When temperature, harmonic and DC bias change at the same time, the transformer operation condition will be more complicated. This paper is the first time to present the measurement research on the magnetic properties of oriented electrical sheet steel considering both different temperature and DC bias, and it shows the curve of magnetic properties under different temperatures (40 °C to 150 °C), frequency(50Hz to 4.5kHz) and DC bias (0A to 2.0A). It can provide a useful guidance for the design and optimization of power transformer

LINK ORIGINAL

http://aip.scitation.org/doi/pdf/10.1063/1.4979490

terça-feira, 6 de junho de 2017

Hybrid DC/DC Converter for Electric Vehicle (EV) On-Board Charger (OBC) Using Full-Bridge (FB) and Resonant Converter with Single Transformer -Department of Electrical Engineering Myongji University Seoul Korea

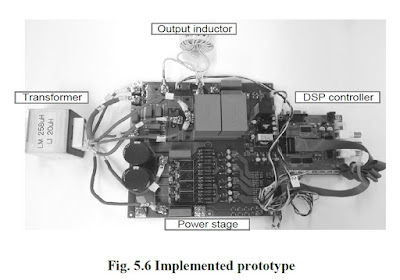

ABSTRACT In this document a highly efficient hybrid DC/DC converter is proposed. Its design procedure, analysis and experimental results are presented by testing of the implemented prototype and. whole document is arranged into six chapters. Electrical vehicle battery chargers background, power level, different charging methods and purpose of the document is presented in chapter 1. High power DC/DC converter topologies suggested recently, and its benefits and drawbacks are briefly discussed in chapter 2. Proposed converter diagram, operational analysis and comparison of proposed converter with other DC/DC converter topologies are presented in chapter 3. Chapter 4 is about design procedure. Based on the design procedure suggested in chapter 4, prototype design and simulation results are given in chapter 5 and experimental results are given in chapter 6. Most of the previously proposed hybrid converters have used two transformers for each converter in hybrid structure that makes the size of the converter bulky and there was also low utilization and the power distribution problem between two transformers of the hybrid converters. To solve this problem, a new high efficient hybrid DC/DC converters using single transformer, which has characteristics of Full-bridge and resonant convertor for EV OBC, is proposed in this thesis. By using single transformer the power distribution problem has been solved and transformer utilization has become high. In the proposed converter, magnetizing inductance has been used at the primary side of the transformer to obtain the soft switching such as zero voltage switching (ZVS). Leakage inductance of the transformer has been used as resonant inductor on the secondary side to avoid the use of separate inductor as resonant. The prototype of 6.6KW has been implemented to verify the feasibility of the proposed converter and maximum efficiency of 97.4 is achieved at 413 V.

This paper proposes a dc/dc converter for electric vehicle onboard chargers using a secondary resonant tank. To attain soft switching characteristics, such as zero voltage switching, magnetizing inductance has been used at the primary side of the transformer. The leakage inductance of the transformer is used as a resonant inductor on the secondary side to avoid the use of a separate inductor as resonance. The proposed converter is applicable for a wide load range. A 6.6KW prototype has been implemented for a wide range of load variations (250V, 330V, 360V, and 413V). A maximum efficiency of 97.4% is achieved at 413V.

LINK VIEW FULL TEXT

http://manuscript.jpe.or.kr/ltkPSWeb/pub/pubfpfile.aspx?ppseq=1333

LINK : http://www.mediafire.com/file/j3todp7qifgn64c/2_JPE-16-06-032.pdf

segunda-feira, 5 de junho de 2017

Digital Control of Bidirectional LLC Resonant Converters* Minjun Park Electronics Engineering, Kyungpook National University, Taegu, South Korea

Digital Control of Bidirectional LLC Resonant Converters* Minjun Park Graduate School of Electronics Engineering, Graduate School, Kyungpook National University, Taegu, South Korea (Supervised by Professor Byungcho Choi)

(Abstract)

This thesis presents the dynamic analysis and compensator design of digitally controlled bidirectional LLC resonant dc-to-dc converter. The digital control scheme employs an additional A/D feedback from the current and voltage of the resonant tank network to overcome the limitation of the existing analog control. The superiority of the digital control over the analog control is verified using an experimental 300 W bidirectional LLC resonant dc-to-dc converter. The digital compensator is designed by emulation approach using bilinear transform. Both of the controllers are verified using PSIM simulation and experimental of prototype hardware.

* A thesis submitted to the Council of the Graduate School of Kyungpook National University in partial fulfillment of the requirements for the degree of Master of Science in December 2013

SEMIKRON Innovation Award and SEMIKRON Young Engineer Award 2017

(from left to right) Prof. Leo Lorenz (ECPE), Johannes Kolb (Karlsruhe Institute of Technology), Mario Gommeringer (Karlsruhe Institute of Technology), Alexander Schmitt (Karlsruhe Institute of Technology), Pierrick Ausseresse (Infineon Technologies), Marco Schilling (Ilmenau Technical University), Bettina Martin (SEMIKRON-Stiftung) Quelle: TILMAN WEISHART PHOTOGRAPHY

Winner of the Semikron Innovation Award 2017

This year’s SEMIKRON Innovation Award went to a team of three engineers: Mario Gommeringer, Johannes Kolb and Alexander Schmitt from KIT Karlsruhe. The award-winning team has developed a new innovative power electronic circuit at the Institute of Electrical Engineering (ETI) of KIT Karlsruhe that will help maximize power output in solar power generators. The new circuit known as the HILEM circuit or “High Efficiency Low Effort MPP Tracking Circuit” can be connected between any number of photovoltaic strings and a common inverter.

Winner of the Semikron Young Engineer Award 2017

This year’s SEMIKRON Young Engineer Award has gone to two young researchers. The first award winner Pierrick Ausseresse from Infineon Technologies was selected for his work on the development of a new digital IC for use in PC power supplies. The other joint winner of the Young Engineer Award is Marco Schilling from Ilmenau Technical University. Mr Schilling’s award-winning development Opti-PAC is a new, versatile tool for optimum active and passive component selection in automotive power systems such as electric drivetrains or DC/DC converters.

LINK ORIGINAL:http://www.ecpe.org/awards/semikron-innovation-awardsemikron-young-engineer-award/

quarta-feira, 31 de maio de 2017

Configurações e modos de operação dos inversores híbridos e seus requisitos técnicos para operação on-grid e off-grid - Prof. Me. Lucas Vizzotto Bellinaso Prof. Dr. Leandro Michels - Workshop inversores híbridos com armazenamento de energia

Configurações e modos de operação dos inversores híbridos e seus requisitos técnicos para operação on-grid e off-grid

Prof. Me. Lucas Vizzotto Bellinaso Prof. Dr. Leandro Michels

Workshop inversores híbridos com armazenamento de energia

Grupo de Eletrônica de Potencia e Controle (GEPOC)

Universidade Federal de Santa Maria (UFSM) Programa de Pos-Graduacao em Engenharia

LINK COM A PALESTRA COMPLETA

http://www.iee.usp.br/sites/default/files/%20Apresenta%C3%A7%C3%A3o_Lucas.pdf

segunda-feira, 29 de maio de 2017

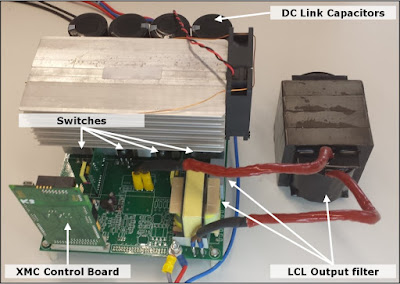

A Practical Study on Three-Level Hybrid SiC/Si Inverters Fabio Brucchi at Infineon Technologies Italia S.r.l. Klaus Sobe and Davide Chiola at Infineon Technologies Austria AG

In today’s PV, UPS and GPI systems, three-phase output inverters are often based on three-level topologies using Silicon IGBTs. This article demonstrates the potential of a hybrid inverter using CoolSiCTM MOSFETs and TRENCHSTOPTM 5 Silicon IGBTs.

State of the Art Three-Level Inverter Topologies Three-level inverters based on Silicon IGBTs are a common design solution giving an excellent cost/performance ratio. As explained in [1]-[3], the technical advantage over the classical two-level B6 inverter represented in Figure 1 (a) is a reduction of switching losses and filtering effort, at the expenses of higher circuit complexity. Two commonly found three-level designs in the low to mid power range are the Neutral Point Clamping Diode and the Neutral Point Clamping Transistor topology, illustrated in figure 1 (b) and (c), respectively.

Figure 1: Commonly used inverter configurations: (a) two-level (B6, Six-Pack) inverter; (b) three-level neutral point clamping diodes (NPC-1, I-Type) inverter; (c) three-level transistor clamped (NPC-2, T-Type) inverter; for each topology only one out of three phases is shown.

SiC Technology Changes the Picture

The unique features of Silicon Carbide (SiC) switches were described in [7] and [8] together with the potential impact on applications. With the emerging SiC semiconductor technology the degrees of freedom for the designer become higher, opening the path to new scenarios: fast 1200V SiC switches can make T-Type inverters attractive for higher frequencies and even the transition back to a two-level solution might be considered in order to achieve higher efficiency and reduce the bill of material [6]. In the following sections, the potential of a hybrid T-Type inverter using 1200V CoolSiC™ MOSFETs and 650V TRENCHSTOPTM 5 IGBTs is demonstrated experimentally. The key benefits of this approach are low conduction and switching losses, relatively low effort for output and EMI filtering and – compared to converters with more than three levels – moderate control effort. Test Setup and Conditions Since this article considers the influence of only the power semiconductors on the system efficiency, all measurements were carried out using a single phase test board and a fixed L-C-L output filter designed by Tecnologie Future S.r.l. and Infineon Technologies Austria A.G. The design goals for this platform were a simple component replacement as well as an easy access for thermal and electrical measurements – not a demonstration of power density or a BOM cost reduction. It should be noted that the absolute efficiency values obtained with a single-phase system do not correspond one-to-one to the values of a three-phase and three-wire system, i.e. a system without exposed neutral. First, the core losses of the filters are different and second the modulation scheme cannot use a third-harmonic injection technique. All devices were operated using an Infineon 1EDI60N12AF driver. This compact, isolated, single channel driver is based on the coreless transformer technology, featuring a high common mode transient immunity – a major requirement when dealing with high speed switches. The output voltage of the drivers is provided using a local HF transformer close to the driver that is fed from one resonant AC link. Using the turn-ratio of the transformer, the gate voltages are set to +15V for turn-on and -5V for turn-off. The single phase inverter was operated at a constant DC link voltage of 720VDC providing a voltage of 230VRMS on the output. Using an electric AC load the output current of the inverter was increased in steps of 1,5ARMS every 5 minutes in order to determine the conversion efficiency for different load situations.

LINK ORIGINAL

https://eepower.com/power-converters/practical-study-three-level-hybrid-sicsi-inverters-infineon-877#disqus_thread

sábado, 27 de maio de 2017

A Study on the Failure Mode of the Battery for Energy Storage System Kim Hee-Jung Department of Mechanical Design Engineering Pusan National University

Abstract

Entering the 21st century, new & renewable energy, electric vehicle (EV) and energy storage system (ESS) have emerged due to more regulations on CO2 gases and depletion of fossil fuels after climate changes. With a leap towards the 'IT Era,' uninterruptible power supply (UPS) has developed into an essential equipment, an emergency power system designed to prevent a blackout. A key element of these facilities is a secondary battery which can be divided into lead-acid battery, Ni-MH, Ni-Cd and lithium ion battery (LIB). In particular, there have been numerous studies on lithium batteries with the following advantages: i) low price for unit volume and energy density by weight, ii) very stable lead-acid and high energy density, iii) long life expectancy. The valve-regulated lead-acid battery (VRLA) designed for power storage has a long life expectancy that is 3,000 times or more at 70% depth of discharge. Since it is a closed type, it can suppress the decrease of the electrolyte level, making maintenance unnecessary. In this kind of the VRLA designed for power storage (e.g. photovoltaic power generation, wind power generation, load leveling, etc.), battery performance and life are dependent upon lead alloy-based grid casting and electrolyte 'gel' mixing technologies. Regarding energy accumulation for optimum system operation, the technology developed to figure out the progress of battery failure is a key factor. The conventional large stationary lead-acid battery is mostly used as a backup against a blackout. Even though its life expectancy increased to 15 years, it is not appropriate for power storage in which charge and discharge are repeated every day. These lead storage batteries have critical effects on battery life and performances depending on their charging system. Therefore, the design of an optimum charge system is crucial for operating an optimum system. In general, the suitability of an optimum charge system is assessed by measuring the degree of battery aging. Hence, this study attempted to derive the optimum charge system setting after assessing the degree of battery aging under diverse load conditions. According to high-temperature accelerated life testing, battery internal resistance almost doubled compared to the early-stage battery when the rated capacity decreased to 80% or less. At the same time, battery surface temperature increased by almost twice as well. The VRLA/GEL was primarily heated in the middle area. It appeared that a gel electrolyte was dried out because of heating, causing increase in temperature. In LIB, diverse cathode materials have been applied since the lithium ion secondary battery comprised of LiCOO2 was first developed by SONY. However, LiFePO4 and ternary battery are currently used most widely. LiFePO4 is 3.2V in operating voltage and 170mAh/g in theory capacity. Even though it is slightly lower than a ternary battery in terms of energy density, it has a low risk of ignition and explosion. Therefore, it is great in terms of battery safety. With the aforementioned properties, a lithium ion battery is advantageous in industrial battery sectors such as x-EV, ESS and UPS. Even so, LiFePO4 reveals very low electric conductivity as an olivine material (LiMPO4, M=Mn, Ni, Co, Fe). This weakness has been greatly improved by coating the surface of the active material with carbon. However, degradation becomes more severe because of increase in battery internal resistance as a cycle proceeds. The objective of this dissertation was to clarify failure mode of the secondary battery for ESS. Therefore, this study located the source of the heat which occurs at battery charge or discharge, using IR SnapShot Model 525, one of the non-destructive testing (NDT) and analyzed the progress of the degradation. Next, the degradation behavior and durability of lead storage battery were compared through the measurement of battery internal resistance. It was found that battery internal resistance almost doubled compared to the early-stage battery when the rated capacity decreased to 80% or less. At the same time, battery surface temperature increased by almost twice as well. The surface temperature and internal resistance of the lithium battery almost doubled respectively because of problems in the manufacturing process and the materials themselves.

Assinar:

Postagens (Atom)

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378