Introduction

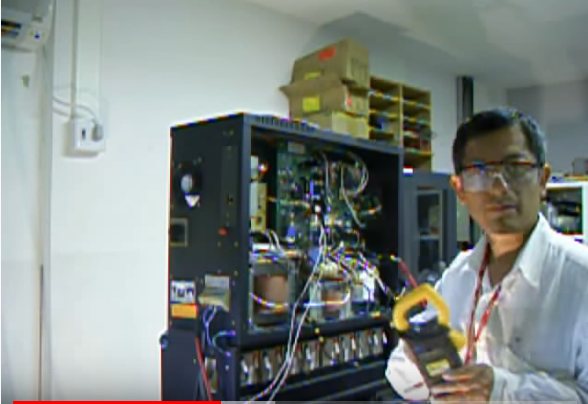

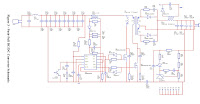

This report describes the design of a 320W Telecoms DC/DC converter. A push-pull forward

converter running with current mode control using the LM5030 from National Semiconductor

delivers high performance and small solution size. Custom planar magnetics from Payton

have been used throughout to reduce component build height, increase efficiency and aid

cooling.

This report contains target specification, schematic, bill of materials, magnetics design

information as well as a detailed design analysis. A full set of performance measurements is

also included taken from the prototype unit shown in Figure 1. Measurements include

conversion efficiency, power stage device temperature rise, line/load regulation, start-up

behaviour, transient load response and loop gain/phase characteristic.

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378