Robin Koffler is the General Manager for Riello UPS Ltd the UK subsidiary of Riello UPS (RPS S.p.A)Choosing between transformer-based or transformerless uninterruptible power supplies may not be a simple ‘either/or’ decision, particularly above 10kVA. Both technologies have their place in today’s power protection scenarios but the key differences between them are: physical size, efficiency, noise output and the levels of input harmonic distortion that they generate.

Both uninterruptible power supply designs produce a tightly regulated source of uninterrupted power but they differ in the way they generate the dc voltage required by their inverters and their output stages.

Transformer-based Uninterruptible Power Supplies: until the early 1990s, the only design of online uninterruptible power supply was transformer-based. Nowadays, the design is still available but generally in larger sizes for UPS from eight to 800kVA. The most common applications for this are large industrial sites.

This type of UPS has a robust transformer-isolated inverter output, which makes it more suitable for the type of application where there is a likelihood of electrical noise; spikes, transients, and potentially, a high degree of short-circuit currents.

The inverter generates an ac supply from its dc power source, which is fed into a step-up transformer. The primary function of the transformer is to increase the inverter ac voltage to that required by the load. The transformer also protects the inverter from load disruption, whilst also providing Galvanic isolation (a method of isolating input and output).

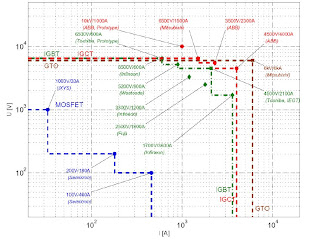

Modern inverter designs use IGBTs (Insulated Gate Bipolar Transistors) in place of more traditional switching components (such as power transistors and thyristors). IGBTs combine the fast-acting and high power capability of the Bipolar Transistor with the voltage control features of a MOSFET gate to form a versatile, high frequency switching device. This in turn has given rise to more powerful, efficient and reliable inverters.

Transformer-based UPS are also supplied with a dual input option as standard, which can be selected at installation by simply removing a linking connector from its input terminal. This allows it to be powered from two separate ac supply sources thus adding further resilience. A transformerless UPS can be installed with dual input capability, with supplies derived from the same source, but this is typically a factory-fit option.

Transformerless Uninterruptible Power Systems

Transformerless UPS is a newer design, commonly available from 700VA to 120kVA. The primary purpose behind the introduction of transformerless units was to reduce the overall physical size and weight thus making an uninterruptible power supply unit more suitable for smaller installations and/or computer room/

office type environments, where space may be limited. It also generates far less noise and heat than its transformer-based cousin and has far lower input harmonic distortion levels making it compatible with environments where electronic equipment (such as

computers) may be more sensitive to this type of distortion.

In place of the step-up transformer, a transformerless UPS uses a staged process of voltage conversion. The first stage combines a rectifier and booster-converter to generate a dc supply for the inverter. An uncontrolled, three-phase bridge rectifier converts the ac supply into a dc voltage. This is passed through a mid-point booster circuit to step the dc voltage up to typically 700-800Vdc from which a battery charger and inverter are powered. In the second stage, the inverter takes the supply from the booster-converter and inverts it back to an ac voltage to supply the load.

An added benefit of this method is that the rectifier can operate from either a three or single-phase input supply. This can be configured at installation for systems up to 20kVA. A control system ensures a stable, regulated dc voltage is supplied to the inverter at all times and the inverter can operate regardless of UPS output load variations or mains power supply fluctuations or disturbances.

Choosing between Transformer-based or Transformerless Uninterruptible Power SuppliesIn many applications the choice between the two may be clear. It is where the two ranges overlap, in terms of power rating, that the decision is more complicated. Consideration needs to be given then to: initial purchase cost, physical size, running costs, the installation environment, and in particular, the levels of input harmonic distortion they generate. Both designs can be operated in parallel to achieve higher levels of availability and resilience.

Over the last decade, the gap between these two uninterruptible power supply technologies has reduced as manufacturers have applied common techniques and research & development efforts to both designs. The driving force behind this has been cost and size, alongside demands to improve operating efficiency and reduce harmonic generation. In terms of online performance, both designs provide the same level of

performance and are classified as VFI systems (voltage and frequency independent - in accordance with EN/IEC 62040-3). Their principal differences are their effects on upstream supplies and the operating environment.

Transformerless UPS are generally recognised as more efficient and having a higher power factor than an equivalent transformer-based design, therefore operating costs can be lower.

Below 10kVA, the transformerless UPS design dominates the online uninterruptible power supply market and has become the standard within data centre environments as they offer a more compact footprint, higher operating efficiencies and lower noise output. However, the strengths of the transformer-based design come into play in the industrial environment.

EXCELENTE ARTIGO DO ENG. ROBIN KOFFLER,ELE E REALMENTE VALIDO NOS MERCADOS EUROPEUS,NORTEAMERICANO,ASIATICO,MAIS NO MERCADO ESPECIFICAMENTE BRASILEIRO ,TERIA QUE TOMAR EM CONTA NOSSA REALIDADE ESPECIFICA,ISTO E,BRASIL E O CAMPEAO MUNDIAL DOS RAIOS,AS DESCARGAS ATMOSFERICAS NAS REGIONES SUDESTE E MAIOR PARTE DO TERRITORIO,SAO DE NATURALEZA INTENSA QUE OS UPS COM TRANSFORMADOR TEM MAIOR VIDA UTIL E ROBUSTEZ QUE OS QUE SAO PROJETADOS SEM TRANSFORMADOR,NESTE CASO OS CIRCUITOS SUPPRESSORES DE SURTOS E DESCARGAS ATMOSFERICAS TRABALHARAM A SUA MAXIMA CAPACIDADE,POR ISSO TEM QUE SER BEM ANALIZADO A ESCOLHA MAS CERTA PARA CADA NECESSIDADE.

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378