domingo, 1 de julho de 2018

sábado, 30 de junho de 2018

Demirchyan K.S., Neiman L.R., Korovkin N.V., Chechurin V.L. Theoretical foundations of electrical engineering. VOL1-VOL-2-VOL3- Демирчян К.С., Нейман Л.Р, Коровкин Н.В, Чечурин В.Л. Теоретические основы электротехники

LINK ORIGINAL EN LA WEB

https://www.texenergo.ru/publication/biblioteka_elektrotekhnika/demirchyan_k_s_neyman_l_r_korovkin_n_v_chechurin_v_l_teoreticheskie_osnovy_elektrotekhniki/

TOMO1

https://www.texenergo.ru/upload/books/nejman_teo_osn_eltex_t1.pdf

TOMO2

https://www.texenergo.ru/upload/books/nejman_teo_osn_eltex_t2.pdf

TOMO3

https://www.texenergo.ru/upload/books/nejman_teo_osn_eltex_t3.pdf

quinta-feira, 28 de junho de 2018

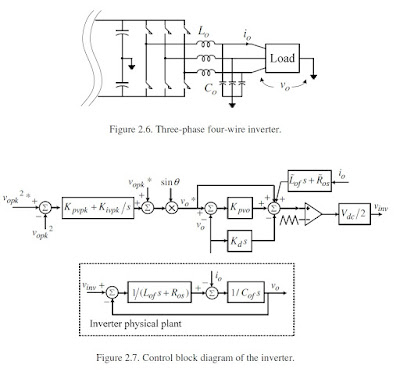

ADVANCED INVERTER CONTROL FOR UNINTERRUPTIBLE POWER SUPPLIES AND GRID-CONNECTED RENEWABLE ENERGY APPLICATIONS By Shuai Jiang- Michigan State University-Electrical Engineering

ABSTRACT

ADVANCED INVERTER CONTROL FOR UNINTERRUPTIBLE POWER SUPPLIES AND GRID-CONNECTED RENEWABLE ENERGY APPLICATIONS

By Shuai Jiang

The advancement of digital signal processors (DSPs) and programmable logic devices in modern power electronics systems offer great control flexibility and capability, providing attractive features particularly for applications in which complex control tasks are involved. This dissertation investigates some DSP based advanced control algorithms for pulse-width modulation (PWM) inverter applications, in particular, voltage regulated inverters connected with AC loads and current regulated inverters connected with utility grids. Uninterruptible power supply (UPS) is a typical example of voltage regulated inverter applications. It is widely used to supply high quality, continuous and disturbance-free AC power to critical loads such as medical equipments, computers and communication systems. A good UPS system requires not only excellent steady state performances in terms of voltage regulation and total harmonic distortions (THD) regardless of unknown load disturbances but also a fast transient response during load step change. In this dissertation, a three-phase four-wire AC-DC-AC double conversion UPS system is first studied. Multi-loop control strategies are designed to regulate the system input currents, DC voltages, and output voltages. Next, study will deep dive into a DC-AC three-phase UPS inverter. A high performance repetitive controller (RC) for the voltage regulated three-phase inverter is proposed. The proposed control algorithm can eliminate all the periodic distortions and guarantees a high quality sinusoidal output voltage under unknown and severely distorted loads. A novel 4th-order linear phase infinite-impulse-response (IIR) filter is first used in the RC such that harmonic distortions up to the 19th order are rejected. In order to achieve fast response during step load transient while still maintaining the low THD feature, a modified synchronousframe approach with significantly reduced delay is later proposed and investigated. Grid-connected inverters utilizing renewable energy sources (e.g., photovoltaic, wind, fuel cell, etc.) are growing rapidly in recent years along with the constantly growing global demand for electricity. A grid-connected inverter injects a synchronously regulated sinusoidal current to the utility grid with required low THD and high power factor. Using an LCL filter in such a system has been recognized as a small size low cost solution due to its -60dB/dec high frequency attenuation. In this dissertation, a high-resonance-frequency LCL filter with minimal size and cost requirement is designed. A proportional plus repetitive control hybrid strategy is then proposed to achieve very low THD current regulation and high power factor. Although utility grid is often modeled as an infinite AC voltage source in inverter current control, it can introduce way more complicated resonance issues particularly when long transmission cables are used between the inverter and the main grid. A real example of an HVAC offshore wind farm system with long submarine cables is then investigated and emulated by a scaled-down 120Vac single-phase system. A systematic analysis is carried out and the key passive component parameters that cause high frequency resonances are identified. A notch filter based active damping control is proposed and implemented in the inverter. When a grid-connected inverter is sourced from photovoltaic (PV) panels, a front-end isolated DC-DC converter is usually incorporated and dedicated control must be employed based on the converter dynamics to achieve both maximum power point tracking (MPPT) and coordination with the 2nd-stage inverter control. A high performance system-level control scheme is designed for the proposed boost-half-bridge converter-inverter system in the PV application.

LINK THESIS

https://d.lib.msu.edu/etd/2193

quarta-feira, 27 de junho de 2018

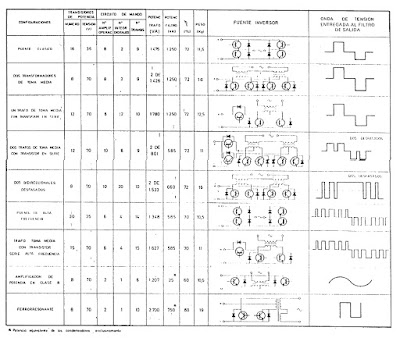

INVERSOR CON TRANSISTORES DISTINTAS SOLUCIONES-TRANSISTOR STATIC INVERTERS VARIOUS SOLUTIONS-J. GUALDA,S. MARTINEZ GARCIA

REVISANDO MIS COPIAS HOY EN CASA ENCONTRE UNAS COPIAS DE LA REVISTA MUNDO ELECTRONICO 1979 - No 86 DE LOS AUTORES PROFESORES J. GUALDA ,SALVADOR MARTINEZ GARCIA,EN ESOS AÑOS ESTABA ESTUDIANDO INGENIERIA ELECTRONICA EN LA UNIVERSIDAD NACIONAL MAYOR DE SAN MARCOS -LIMA-PERU

LINK

http://www.mediafire.com/file/zaljldu59zlntjs/INVERSOR%20CON%20TRANSISTORES.pdf

LINK

http://www.mediafire.com/file/zaljldu59zlntjs/INVERSOR%20CON%20TRANSISTORES.pdf

segunda-feira, 25 de junho de 2018

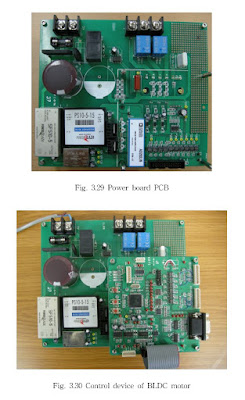

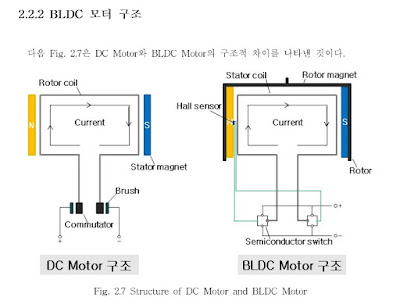

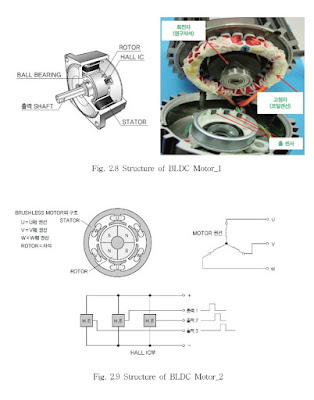

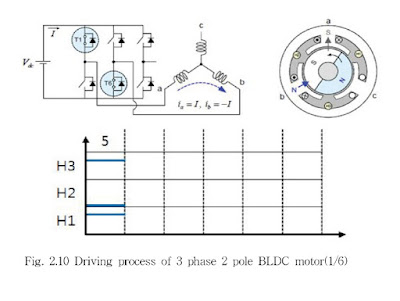

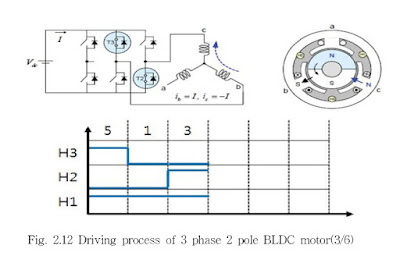

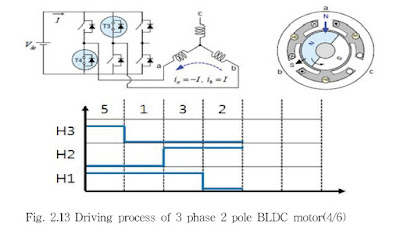

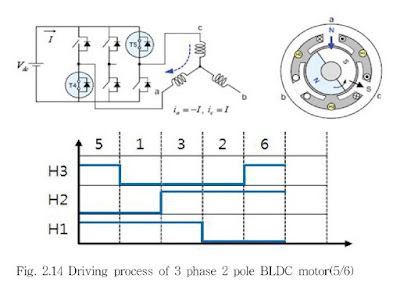

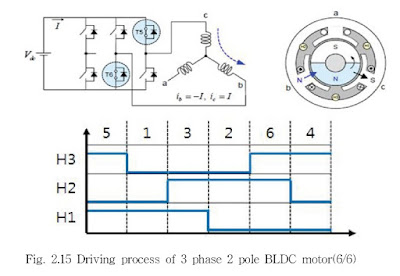

A Study on the Development of BLDC High Efficiency Motor for Electric Vehicle Drive By Jung, Bo-Won Department of Mechanical Engineering Graduate School of Chosun University

A Study on the Development of BLDC High Efficiency Motor for Electric Vehicle Drive By Jung, Bo-Won

Department of Mechanical Engineering Graduate School of Chosun University

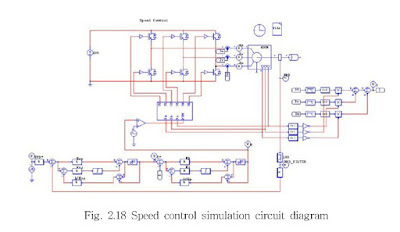

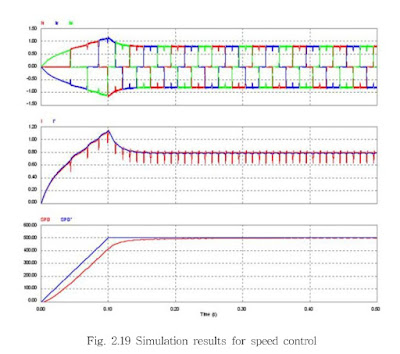

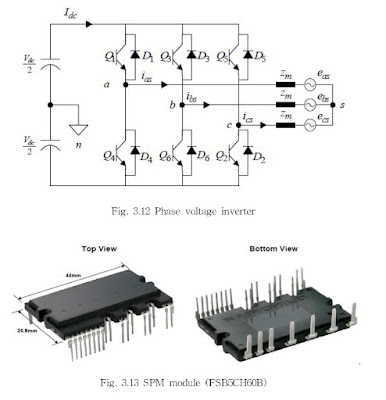

In the past, the automobile industry market showed off the large displacement and high-power & high-performance technical power focusing on internal combustion engine. Due to the instability of oil price, however, it started developing/mass-producing vehicles with low displacement & high fuel-efficiency. Thus, the domestic automobile industry is continuously growing into the national core industry by developing vehicles with low displacement & high fuel-efficiency. However, because of car exhaust after using fossil fuels for a long time, the environmental problem is largely highlighted, and the issue of climate change was discussed with the development of automobile industry. Therefore, the environment-friendly trend could be found in the recent world automobile industry. On top of electric car, the R&D of environment-friendly vehicles such as fuel cell vehicle and hybrid vehicle is actively performed. In case of environment-friendly vehicles, they are driving only with electric motor without engine, or the engine and electric motor are composed as serial, parallel, or serial-parallel. When driving, the high-efficiency driving is possible by combining engine and electric motor. When braking, as equipped with the regenerative braking ability to collect energy, the fuel-efficiency could be improved more than 50% compared to the existing vehicles. The representative cases of environment-friendly vehicle include hybrid vehicle, fuel cell - X - vehicle, and electric vehicle driven by electric motor. Among them, the electric motor application technology which is the most core technology is represented as the technology of environment-friendly vehicle, so that the technical demand for it is increasing. In the world motor technology area, products for microminiaturization, high-speed, high-efficiency, high-power, and light-weight are rapidly growing. Especially, with the increased interest in environment, environment-friendly products are forming new markets. There have been active reinforcement of regulations and technical development to meet such demands for this R&D and also to reduce power consumption. Especially, due to the intensified environmental problem, drivers' interest in electric vehicle is increasing. The great amount of subsidies from government/local governments is also a factor that promotes the purchase of electric vehicles. Moreover, once the autonomous function is added to no noise, no exhaust, light-weighted engine design, and high-tech driver's seat, it is the model of the 4th industrial revolution. Currently, for the development of BLDC motor using the semiconductor switching element after removing the commutator and brush, on top of motor manufacturing businesses in the core parts industry of future automobile, even home-electronic motor manufacturers and industrial motor manufacturers are jumping in the business based on their great interest in researches on product development and quality improvement. Compared to the brush-type DC motor, the BLDC motor has better durability, and high-efficiency and high-power. As there is no brush, the electric noise and mechanical noise are less, so that there is no need of maintenance/repair work. On top of high-speed, its reliability is also high. Compared to other DC motors and AC motors, the BLDC motor has more strengths as a driving motor of electric vehicle. In spite of its high price, it has a long life and great efficiency, so that it has been a lot researched as a driving motor of electric vehicle. This paper aimed to develop the BLDC motor & driver as a driving system of 60kW-level electric vehicle. Completing the development of motor & controller for the PWM control in accordance with high-performance speed control of BLDC motor drive, the Maxwell Program was used for the detailed interpretation of the designed motor. Using the dynamo measuring system, the performance relation of motor efficiency was verified. The results of a series of motor performance test are like below. 1. In order to measure the test results of maximum output, the inverter input was measured as input voltage(VDC) 310V. The motor output was torque(Nm) 102.933Nm, the rated revolutions were 5,560rpm, and the rated output was(KW) 60.02KW. 2. In the results of the motor performance assessment by changing the angle of hall sensor by 5°, 10°, and 15° after producing a BLDC motor, when the speed value was high, and the values of torque, voltage, and watt were low, the performance efficiency was the highest. 3. In the results of dynamo test, when changing the angle of hall sensor by 5°, the maximum torque was 102.933Nm. When the maximum revolution speed was 5,560rpm with voltage(308.1V) and watt(60.02KW), the motor showed the maximum efficiency, which verified the excellence of the motor. As PWM has high efficiency, high power-factor, and high performance, it gets the limelight in the application area of drive. As the motor could be driving in a certain torque area, certain output area, and extensive driving speed range, more things could be expected from future researches. Owing to the excellent control algorithm in the aspect of responsiveness, linearity of control, switching frequency, and high-frequency percentage of output current, it is applied to many drive systems. In the future, regarding the BLDC motor & drive system for high-performance & high efficiency electric vehicles, it is expected to apply the technology to auto part-related companies, and also to contribute to the commercialization of environment-friendly electric vehicles.

Assinar:

Postagens (Atom)

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378