https://zapdf.com/development-of-high-power-high-frequency-magnetics-for-the-f.html

quinta-feira, 5 de julho de 2018

quarta-feira, 4 de julho de 2018

Development of High Power, High Frequency Magnetics for the Future Power Electronics Applications. Kapila Warnakulasuriya, Carroll & Meynell Transformers Ltd, UK,kapila@carroll-meynell.com Farhad Nabhani, Teesside University, United Kingdom

Development of High Power, High Frequency Magnetics for the Future Power Electronics Applications. Kapila Warnakulasuriya, Carroll & Meynell Transformers Ltd, UK,kapila@carroll-meynell.com Farhad Nabhani, Teesside University, United Kingdom, F.Nabhani@tees.ac.uk Vahid Askari, Teesside University, United Kingdom, v.askari@tees.ac.uk

Abstract

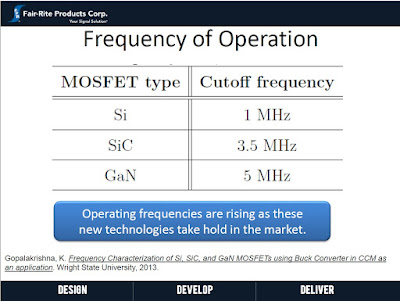

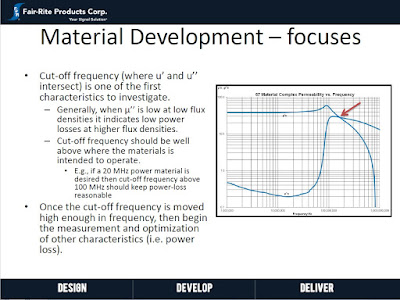

In this paper the optimum design of high power high frequency magnetics is discussed based on a 50kW application operating at 50 kHz. An in depth theoretical explanation on minimizing the losses at high frequency is discussed. A novel approach to the windings that makes the high frequency conductor losses due to proximity effect almost frequency independent is presented. Theoretical explanation of this phenomenon is given. Further how this approach will make it possible to develop a new generation of magnetics that enable power electronics designers to go for significantly high operating frequencies is discussed. The challenge of handling high temperature rise due to high power density of such high power high frequency magnetics is addressed in this paper with a practical solution for that. The theoretical findings are verified based on a set of prototypes developed for a 50kW DC DC converter operating at 50kHz. 1. Introduction Energy efficiency, low noise, reduced mass and dimensions are becoming more and more vital factors in designing magnetics for all kinds of modern power electronics applications such as rolling stock, renewable energy and similar applications. In order to achieve high degree of miniaturization, designers move into significantly high operating (switching) frequencies in the development of modern high power converters and inverters. There is also a clear trend that the operating frequencies used in these applications will continue to increase. Applications like traction, ship and basically any mobile platform with a converter on board require light weight and compact converters to exploit the space available on board more effectively. They often require galvanic isolation for safety or other reasons. Therefore high power high frequency transformers which offer galvanic isolation and a small volume are of increased importance [1]. In addition to the galvanic isolation magnetic components including transformers and inductors perform functions of harmonics filtering, energy storage, level shifting, current sensing and parameter matching for power stages as well as control circuitries in a power converter. They often determine the converter size [2], [3]. It has been a long held view that with a continuous increase in operating and /or switching frequency a continuous decrease in physical size of magnetics would follow. However the heat removal surface of the magnetic components decreases as a result of the higher density design; on the other hand, core and winding loss densities increase correspondingly. Therefore attention needs to be paid to magnetic material selection and associated core loss calculations, especially for high frequency high density magnetics and power converter design [2]. The selection of suitable core material out of several Ferrite grades and Nanocrystalline materials is discussed in this paper with modern approaches of estimating core losses in each type under non sinusoidal excitations of high frequencies such as 50kHz. The advantages of Nanocrystalline that the author has discussed in [11] for 20kHz applications reduce to some extent at this 50kHz application. The effects that high frequency currents such as 50kHz square and triangular waveforms have on conductor losses are explained. A novel winding technique that brings down the significance of proximity effect at high frequencies in transformer windings is presented in this paper. Several core material options such as Ferrite and Air cored inductor are discussed for the series inductor of converters operating in the range of 50kHz. Further a method of minimizing high frequency conductor losses of inductor windings carrying 50kHz currents of significant amplitudes is presented. A novel cooling technique for these compact magnetics with high power densities is discussed. A set of prototypes were developed based on the theoretical findings and tested on a DC/DC converter. Verification of theoretical findings based on practical observations is carried out.

LINK

https://zapdf.com/development-of-high-power-high-frequency-magnetics-for-the-f.html

Performance Comparison of Nanocrystalline Material with Ferrite in a 40kW 20kHz Application Kapila Warnakulasuriya, Carroll & Meynell Transformers Ltd, UK Farhad Nabhani, Teesside University, United Kingdom,

Performance Comparison of Nanocrystalline Material with

Ferrite in a 40kW 20kHz Application

Kapila Warnakulasuriya, Carroll & Meynell Transformers Ltd, UK,kapila@carroll-meynell.com

Farhad Nabhani, Teesside University, United Kingdom, F.Nabhani@tees.ac.uk

Vahid Askari, Teesside University, United Kingdom, v.askari@tees.ac.uk

Abstract

In this paper the performance of Nanocrystalline material in comparison with ferrite is evaluated for a high frequency high power transformer core application. The major advantage of Nanocrystalline material over ferrite is its ability to go for higher design flux densities. However, this is limited with increased losses occurring with the increase of operating frequency. The situation is studied for a 40kW, 20 kHz application. Samples of both versions are developed and a performance evaluation is made on the application. Based on the practical outcome a comparison is made in terms of power density per physical parameters such as weight and volume. The cost and manufacturability are also discussed.

1. Introduction

The transformers in electrical systems are responsible approximately to one third of total network losses. These losses are accounted as power quality costs, costs to society and to the environment itself [19]. With the development of power electronics techniques, pulsewidth modulated inverters (PWM) are widely used to control electrical machines, to feed transformers and to interface renewable energy systems. Also in the future DC electric power systems, high power DC –DC converters will play a major role as they will substitute today’s bulky 50/60 Hz transformers [17], [20]. The main purpose of high frequency operation of such power electronics circuits is to reduce the physical size and cost. The implication being that the losses and efficiency become of paramount importance because of the need to remove heat from the small surfaces [16]. High frequency transformers in such a power electronics circuits constitute a major proportion of the weight and losses. Thus, there is a rapid increase in the industry demand for the best optimization of high frequency transformers. The importance of looking into all the options of optimization become further more significant with the increase of amount of power handled. In this paper the design optimization of a 40kW High frequency transformer operating at 20kHz application is discussed. The losses in the core as well as in the windings are analyzed. Theoretical explanations on the principles used in optimizing the core and winding losses are discussed. Attention is given to make a comparison of the performance of nanocrystalline core and ferrite core. The design approach discussed below is used to arrive at optimal designs with each core material.

http://www.mediafire.com/file/69am6c2642rrvx4/TRANSFORMADOR%20FERRITE.pdf

segunda-feira, 2 de julho de 2018

Grid-tie inverter cooperating with renewable energy sources used for voltage quality improvement Ph.D. THESIS Łukasz Rosłaniec WARSAW UNIVERSITY OF TECHNOLOGY

Grid-tie inverter cooperating with renewable energy sources used for voltage quality improvement

Ph.D. THESIS Łukasz Rosłaniec

WARSAW UNIVERSITY OF TECHNOLOGY - Faculty of Electrical Engineering

Abstract

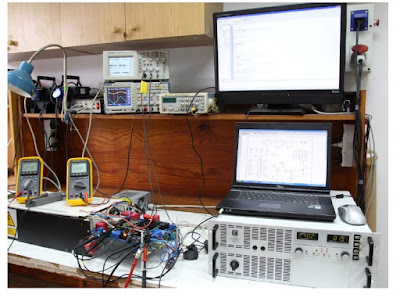

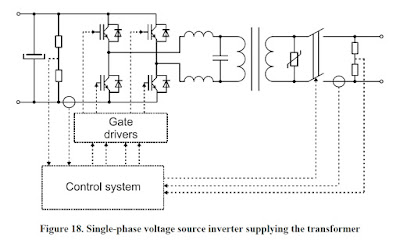

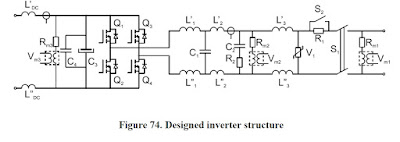

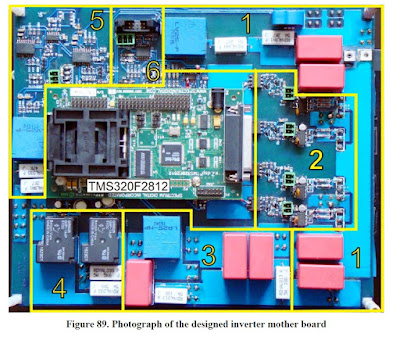

The dissertation centres on a single-phase voltage-source grid-tie inverter design and construction aimed at interconnecting various small-power renewable energy sources (RES) with an electric power system. It also provides the explanation of application areas for this kind of devices. A great part of the research addresses the problems arising from the influence of small-scale RES on the electric power quality in a low-voltage distribution grid the devices are mostly interconnected with. Therefore, the analysis of standard requirements regarding the interconnection of RES with the grid was included in the study. The thesis also characterizes the range of possibilities which voltage source inverters open up to help maintain power quality around the point of common coupling (PCC) during voltage disturbances caused by the receivers. An overview of a hardware design with an emphasis on output filter and control schemes for currently used single-phase inverters serves as a basis for describing the inventions introduced to the prototype. In the final section the simulation and experimental results of the designed inverter are presented and discussed..

FULL THESIS

https://repo.pw.edu.pl/docstore/download/WUT23082068df74474098925967751c9e84/Ros%C5%82aniec+%C5%81ukasz.pdf

Assinar:

Postagens (Atom)

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378

JOSIL ARTISTA PLASTICO FORTALEZA CEARA BRASIL AV.HERACLITO GRAÇA 41 TEL(85)32542378